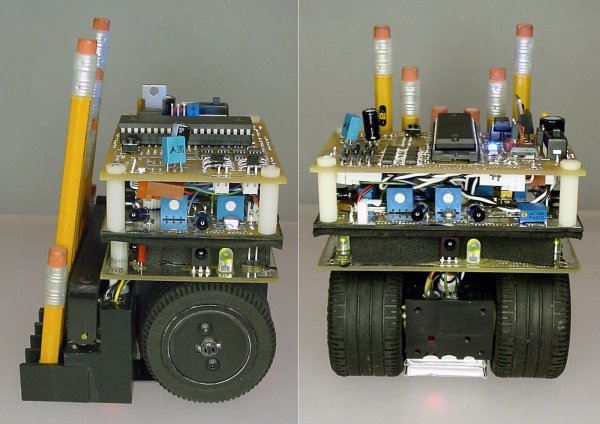

Appetizer solar robot.

There are two major style changes: - Firstly, this robot drags the capacitor rather than pushing it.

- Secondly, this robot carries its solar panel in front of it, like an appetizer tray.

Solar Robot Video

Video of Appetizer solar robot.

Click the above picture to see a video of Appetizer walking (or popping) in the early afternoon Colorado sun at 9,000 feet high. The video hasn't been sped up; this is the actual pace. Solar Robot Schematic

Wiring diagram / schematic for a robot powered by a solar cell.

This is a schematic of a circuit that I altered slightly from Dave Hrynkiw's schematic. I posted the following questions on this page without thinking about who might read it. Turns out that Dave Hrynkiw himself kindly provided his thoughts and answers. Thanks Dave! #1a Since they act like switches, transistors Q1N and Q2N appropriately don't have loads connected to their respective emitters. But then shouldn't they have current-limiting resistors (like 1 kilohm) connected to their bases? It would seem current is being wasted.

Dave responds: You know, that's a good point, and I don't think I've ever tried that. Just by looking at it, I think the issue may be suspending the 3906 collector too high above ground for it to remain on.

#1b It would also seem that there's a voltage drop problem from power (2.5 V) through Q1P (-0.6 V) through Q1N (-0.6 V) to ground (0 V). Where'd the other 1.3 V go? Using a 1 kilohm resistor at Q1's base would source the voltage drop.

Dave responds: That's controlled by the 3906's base current (R1). Again, a resistor on the pnp collector may suspend the 3906 too high above ground to be effective. Good idea tho - worth a try.

#2 Why use bipolar-junction transistors? In a current-poor environment (solar power), why not use MOSFET transistors?

Dave responds: Bipolar transistors are used because they are very inexpensive and most FETs run better at high voltages. We have some Zetex ZVN2106's that work very well, but cost almost 10X more than a bipolar.

#3 Are the photodiode symbols in backwards? What about the solar-cell symbol? I thought I read somewhere that the arrow for these kinds of devices is reversed from regular diodes.

Dave responds: The photodiodes are in "backwards". When reverse-biased, they respond *very* quickly to changes in light intensity, leaking current proportional to the light. In forward-biased mode (as you show), they actually use the photoelectric effect to generate power (ie: 0.5V solarcell), which actually tricks the 1381 into triggering prematurely, as you're generating a voltage, which adds to the system voltage. Both techniques work in this circuit.

The solar-cell symbol should be like a battery stack, with arrows going into it.

These issues occurred to me after finishing Appetizer, which is free-form soldered. Therefore, I couldn't test these ideas to see if a problem exists nor if my suggested corrective measures work. Dave responds: You know, that's a good point, and I don't think I've ever tried that. Just by looking at it, I think the issue may be suspending the 3906 collector too high above ground for it to remain on.

#1b It would also seem that there's a voltage drop problem from power (2.5 V) through Q1P (-0.6 V) through Q1N (-0.6 V) to ground (0 V). Where'd the other 1.3 V go? Using a 1 kilohm resistor at Q1's base would source the voltage drop.

Dave responds: That's controlled by the 3906's base current (R1). Again, a resistor on the pnp collector may suspend the 3906 too high above ground to be effective. Good idea tho - worth a try.

#2 Why use bipolar-junction transistors? In a current-poor environment (solar power), why not use MOSFET transistors?

Dave responds: Bipolar transistors are used because they are very inexpensive and most FETs run better at high voltages. We have some Zetex ZVN2106's that work very well, but cost almost 10X more than a bipolar.

#3 Are the photodiode symbols in backwards? What about the solar-cell symbol? I thought I read somewhere that the arrow for these kinds of devices is reversed from regular diodes.

Dave responds: The photodiodes are in "backwards". When reverse-biased, they respond *very* quickly to changes in light intensity, leaking current proportional to the light. In forward-biased mode (as you show), they actually use the photoelectric effect to generate power (ie: 0.5V solarcell), which actually tricks the 1381 into triggering prematurely, as you're generating a voltage, which adds to the system voltage. Both techniques work in this circuit.

The solar-cell symbol should be like a battery stack, with arrows going into it.

Solar Power

The solar panel (D3) stores power in a capacitor (C3). The voltage in the capacitor increases as the capacitor fills up. Either the left (U1) or right (U2) voltage-detector trips when there's a large enough voltage available, in this case between 2 and 2.5 volts.Robot Movement

When the left voltage-detector trips, a transistor (Q1N) is turned on. This allows current to flow through the left motor (M1), which causes the robot to move forward by spinning to the right.Almost immediately, the power remaining in the capacitor (C3) drops below the voltage-detector (U1) trip point. Another transistor (Q1P) keeps the remaining current flowing through the motor, so that the motor actually gets enough current to result in movement.

A resistor (R1) determines the lowest shut-off voltage. The lower the resistance, the lower the voltage delivered to the motor before shutting off. If the voltage is below the amount needed to cause the motor to turn, the remaining current is just wasted (turned into heat instead of motion) below that voltage point.

The right motor moves using almost the same circuit design as the left motor. However, the left motor is connected backwards (reverse-polarity) since the left motor must spin the opposite direction in order to move the robot in the opposite direction.

Electronic parts labeled on solar robot Appetizer.

Direction

To steer, the amount of light to the left and the right of the robot affects the amount of voltage dropped through two photodiodes (D1 and D2). Only one of the photodiodes usually permits their associated voltage detector to trip, resulting in a left turn, right turn, or side-to-side forward stagger.A potentiometer (R3) balances voltage-drop between the photodiodes to correct minor differences in motor efficiency, weight loading, circuit resistance, and so on. After repeated manual fine-tuning of the potentiometer, the robot can generally proceed directly toward a light source, rather than veering off.

Photon Food Hunting

Solar-powered robots are photovores (Greek for "light-eaters"), which necessitates a light-seeking technique.The light sensor on the right side (D1) of the robot trips the motor on the left side (M1), and vice-versa. This is needed for brightness on the left side to cause the robot to move left, because activation of the right motor moves the robot forward and to the left.Implementation

Parts

Nearly all the parts were purchased from Solarbotics.As of 2008, the Panasonic Voltage Trigger MN1381-C is still available from Solarbotics; search for 1381C. Or, it can be purchased from DigiKey as 1381SC (the letter S indicates the lead-free version). Tip: The datasheet is labeled 1380 not 1381, since that is the base part number of the family.

As of 2008, the exact solar cell is no longer available. However, any medium-size solar cell with a voltage between 3V and 5V will do.

Glue Gun

Every part of the robot connects by solder. The only exception is the motors, which are connected to the robot's body by glue from a hot-glue gun. The glue is lightweight, slightly flexible, and strong; maybe too strong.After connecting the plastic back portion of the motors to the plastic casing of the potentiometer, I'm unable to remove the motors without possibly ripping off their backs. It's too bad, because the robot would perform better if the motors were angled more perpendicular to the ground (greater forward motion) and farther back (to place the center of gravity directly over the motors).

Heat-Shrink Tubing

Tubing covers the leads of most of the components. It isn't necessary to actually shrink the tubing, just slip it over the leads. The tubes protect against shorts, allow for tighter packing, decorate, and color-code connections (ground, positive voltage, or signal).Additionally, tubing on the shafts of the motors (instead of wheels) provides traction. I tried using tiny LEGO wheels as well as homemade glue-gun glue cross sections as wheels. In both cases, even the larger pager motors failed to turn when wheels were attached.

Cell-Phone Motor Torque

I tried using cell-phone vibrating motors. Unfortunately, the robot didn't move at all! The cell-phone motors simply don't have enough torque.Lifting the robot off the ground caused the motors to spin appropriately and showed that the motors were working. Adding a lithium cell for a steady 3 volts (rather than 1.2 to 2.5 volts) didn't help. (Lithium coin cells don't provide high current.) Adding a 3-volt power line (for plenty of available current) allowed the robot to continue moving, but didn't allow it to start moving from a still state. That's how I know the motors are the weak link, not the power source.

I suppose the only option is to gear down those kinds of motors. But solar power doesn't provide much total current per blast, so if you try to make a gearbox out of Lego gears then it may not be enough to move an entire tooth before it stalls.

Future Solar Robot Designs

- Although the robot works well in sunlight, it's pathetic with indoor lighting. I'd like to design a solar engine that would pump-up small voltages, perhaps from a group of smaller capacitors and into a large storage capacitor.

- To further reduce weight and size, soldering together surface-mounted components might produce a really peppy B.E.A.M. robot.

- Even with touch sensors and greater spunk, I'm not sure the behavior will ever be as exciting as a microcontroller-based robot.

Appetizer was a lot of fun to build!

2. Using the paper template as a visual guide, lower a 3/8 end mill (from an eBay auction, MSC Direct.com, or McMaster-Carr) to check for the proper horizontal position.

2. Using the paper template as a visual guide, lower a 3/8 end mill (from an eBay auction, MSC Direct.com, or McMaster-Carr) to check for the proper horizontal position.

No.2 (pronounced "number two") is built on the strengths of the successful drivetrain and wheelbase of Roundabout Sumo. Two large LEGO 49.6 x 28 VR tires provide significant traction. You can find the tires on some LEGO models in most toy stores. But, to save money and to obtain only the specifically required parts, I usually get my LEGO wheels from BrickLink.com or eBay.com.

No.2 (pronounced "number two") is built on the strengths of the successful drivetrain and wheelbase of Roundabout Sumo. Two large LEGO 49.6 x 28 VR tires provide significant traction. You can find the tires on some LEGO models in most toy stores. But, to save money and to obtain only the specifically required parts, I usually get my LEGO wheels from BrickLink.com or eBay.com.